ASUS IoT AISInspection

Collaborating Partner

AI Solution Dept.

at ASUS HQ

(Taiwan)

Work

UI/UX Design

Motion Graphic Design

Date

2021-2022

Tool Used

Adobe XD

Adobe After Effects

Background

ASUS Smart Factory integrates Internet of Things (IoT) and Machine to Machine (M2M) Industrial 4.0 solutions, further incorporating AI solutions to enhance factory production quality and efficiency, while reducing costs.

Solution

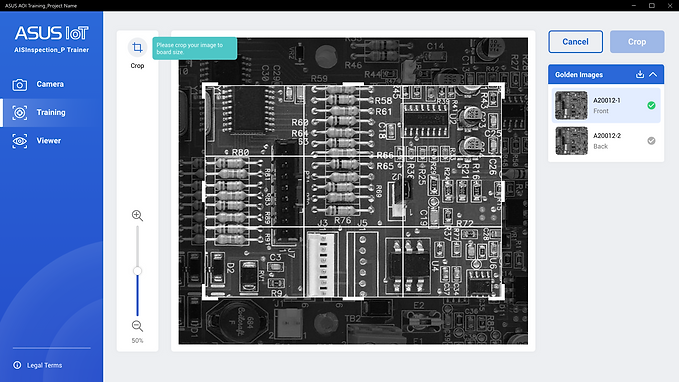

DIP pre-soldering AI defect detection equipment is used for comprehensive defect detection of component placement for PCB hand-inserted connectors before entering the soldering furnace. It provides warnings for missing components, reverse polarity, skewing, and incorrect components, aiming to prevent these issues and reduce rework. Only a small number of good products are needed to complete AI training, while preserving historical inspection data for production traceability or integration with production systems based on customized requirements.

Research & Planning

Enough space for reviewing the images is required

.png)

Transform the control panel of a ultrasound scan machine into the user interface of applications

.png)

Usability Test

Windows Desktop APP

.png)

.png)

.png)

.png)

.png)

Design System